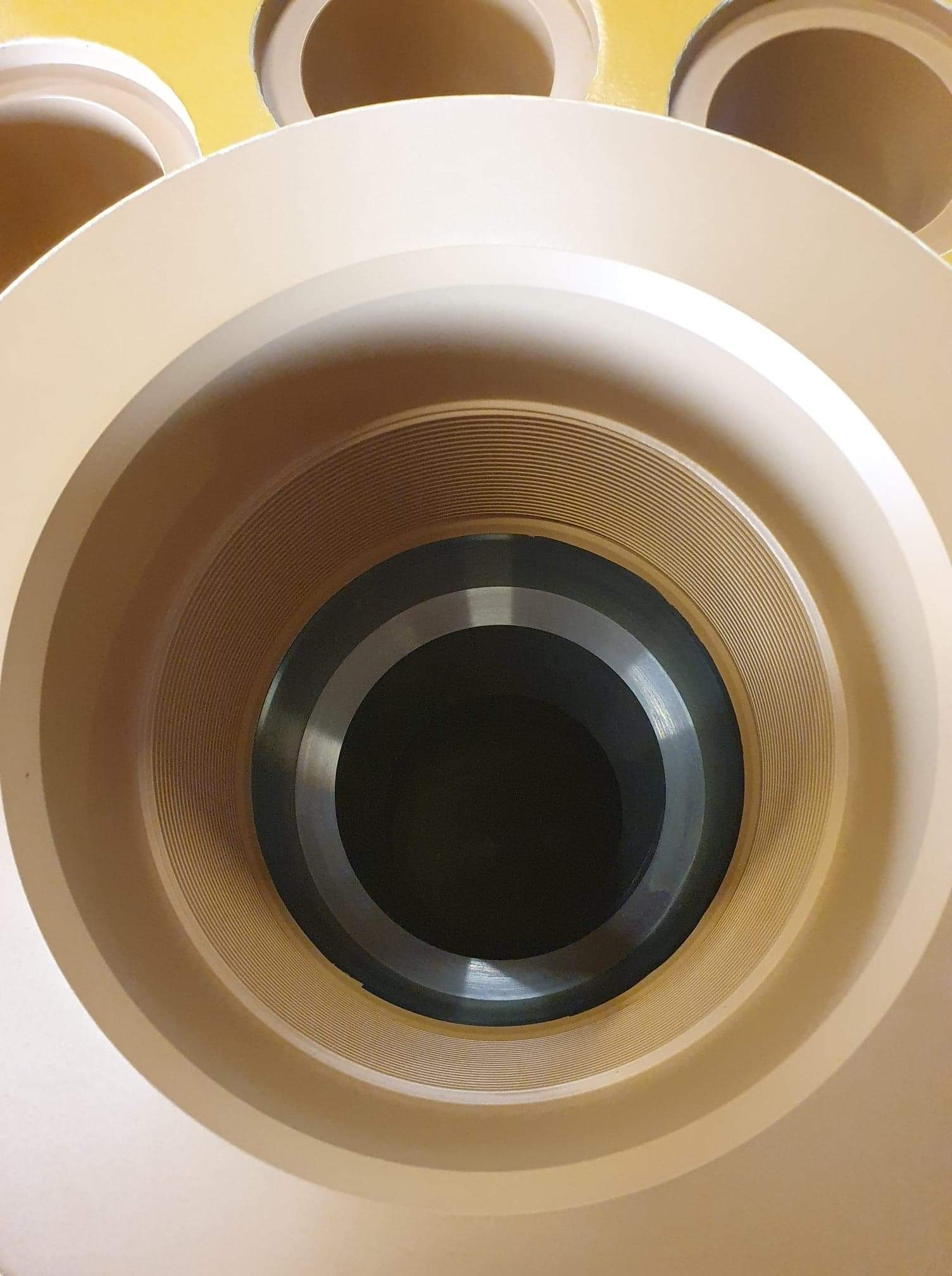

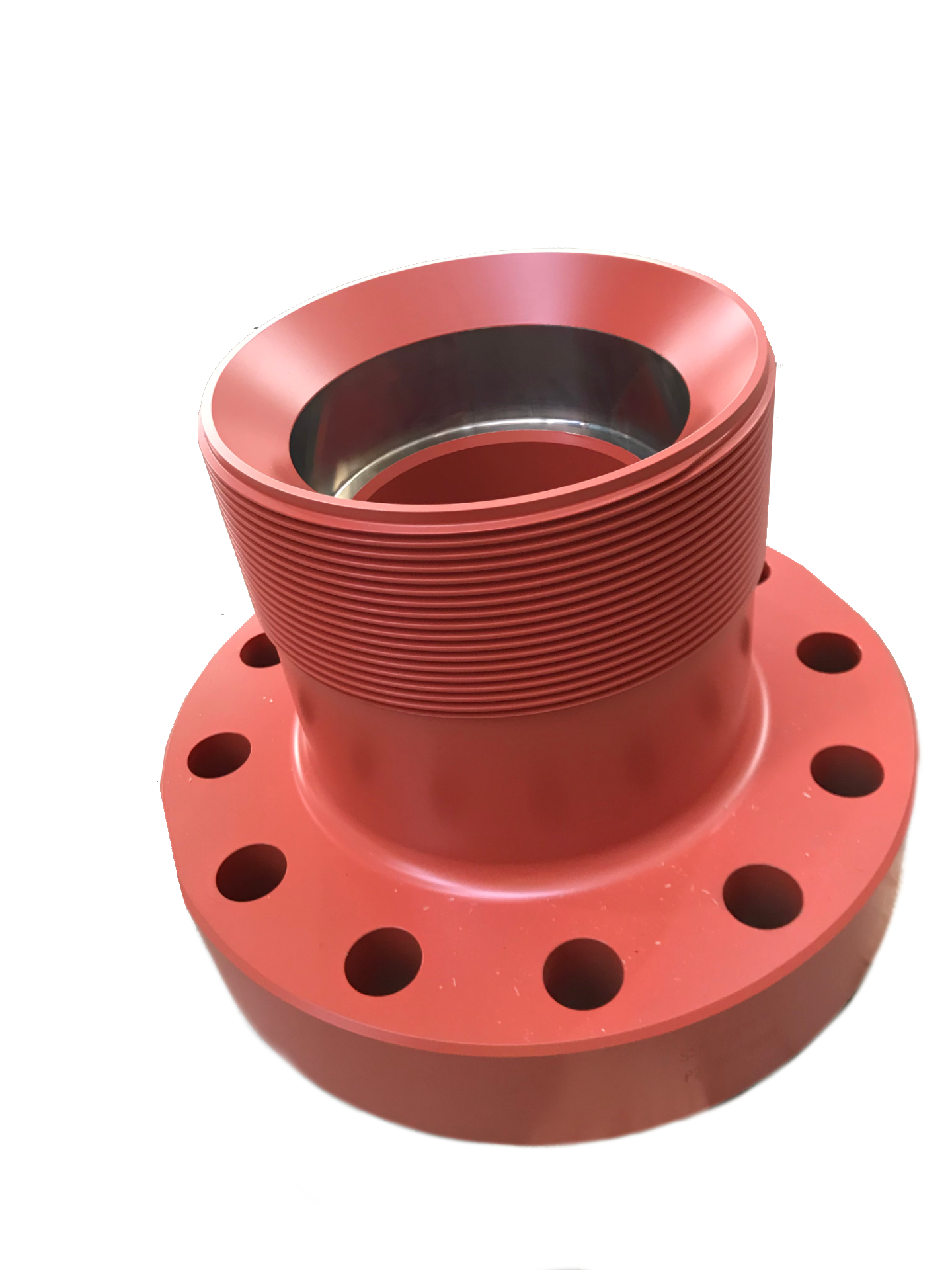

A specialized riser joint designed with a taper to control curvature and reduce local bending stresses and often the riser exposed for highest loads in the string.

Our Stress Joints in grade A707 3W have been supplied to recent Shell projects, e.g. Stones, Appomattox and Vito.